Video Clips

Axi-vision Camera and 3D Television

In collaboration with the NHK team, Iizuka's team invented the Axi-Vision Camera,

which is a 3D television camera that can capture depth images simultaneously

with the color image. Click the demo buttons to view various effects created

by means of the Axi-Vision Camera.

For further details please refer to the electronic online journal Optics

Express of the Optical Society of America http://www.opticsexpress.org/abstract.cfm?URI=OPEX-12-12-2781

Fiber Optic Labs from Around the World

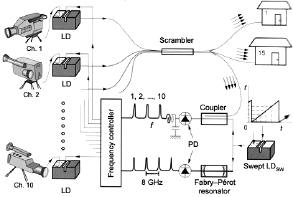

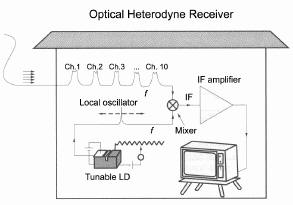

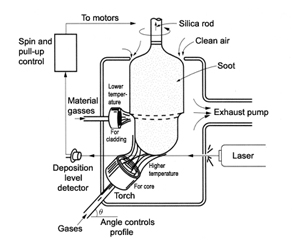

Iizuka produced "Fiber Optics Labs from Around the World," an educational

video sponsored by IEEE, to give viewers the opportunity to visit word renowned

research centers and explore the latest developments in fiber optics. Click

the buttons in the sections below to view segments from this video, posted with

permission from IEEE.

|

| Copyright © 1994 IEEE. Reprinted from “Fiber

Optics Labs from Around the World,” IEEE Educational Video Productions,

1994. This material is posted here with permission of the IEEE. Internal

or personal use of this material is permitted. However, permission

to reprint/republish this material for advertising or promotional

purposes or for creating new collective works for resale or redistribution

must be obtained from the IEEE by writing topubs-permissions@ieee.org.

By choosing to view this document, you agree to all provisions of

the copyright laws protecting it. |

|