Professor Michael Piggott

Professor Michael Piggott

Professor Emeritus Michael R. Piggott, ARCS, PhD (

Brought up in

There he was put to work in the new area of composite materials. A.E.C.L. had great hopes for reinforced aluminiums for pressure tubes for nuclear reactors. So he applied his thin film knowledge to the potentially devastating reaction between silica, the only fibre worthy of consideration for nuclear reactors at that time, and aluminium, the most hopeful matrix material for use in the hot and radiation-filled nuclear reactor environment. He made the discovery that the reaction was immediate, thus conflicting with prior work. He thus set off on the lonely road of enquiry followed by those without preconceptions. (Unlike his predecessors, he merely did the experiment with pure materials, and with no impediments, e.g. oxide films.)

He came to the University in 1968 as a member of the Materials Centre. He was assigned to Chemical Engineering. A blessing, because he found himself having to learn about polymers, and realised their great potential for reinforcement. So he gradually switched over from reinforced metals. Plastics are so much easier.

He proceeded to amass papers to ensure that he was on an ascending spiral of more research papers => more research funds => more graduate students => more experimental results => more papers => more research funds .............. ever upward, till he retired from active research to make way for others.

Now he has enough papers, books and citations to appear in Marquis Who’sWho in the World, along with other notorious people like Colonel Gaddaffi and Fidel Castro. Perhaps justly notorious. His graduate students have shown, in their experiments, that one prominent early theory led researchers down a blind alley (fibre/matrix interface studies) and poor experiments, performed early on, gave angle ply laminates such a bad name that they haven’t ever been used in the aircraft industry, despite their irrefutably sterling qualities. Furthermore, he and one of his students discovered that shear failure in polymers was really tensile failure with rotation.

For relaxation he has climbed six virgin peaks in the Canadian Arctic, built two cottages, has been editor-in-chief of the North Renfrew Times, sung with the Canadian Opera, and enjoys the occasional company of his six far-flung grandsons (no granddaughters, alas).

He can be available to discuss with, and advise, bona fide students and faculty on fibre reinforced materials, by appointment through gorette.silva@utoronto.ca or directly by email: micranpiggott@gmail.com

Some important

papers showing the wide range of his group's research

- M.R. Piggott and B. Harris, "Compression Strength of Carbon, Glass and Kevlar-49 Fibre Reinforced Polyester Resins", J. Mater Sci. 15, 2523-38 (1980).

- M. Woo and M.R. Piggott , "Water Absorption of Resins and Composites II: Diffusion in Carbon and Glass Reinforced Epoxies", J. Comp. Tech .Res., 9, 162-166 (1987).

- P.W.K. Lam and M.R. Piggott, "The Durability of Controlled Matrix Shrinkage Composites; II: Fatigue Properties of Carbon Fibre-Epoxy Copolymer Pultrusions", J. Mater. Sci., 24, 4427-4431 (1989).

- S-R Dai and M.R. Piggott, "The Strengths of Carbon and Kevlar Fibres as a Function of Their Lengths", Comp. Sci. Tech. 49, 81-87, (1993).

- M.R. Piggott and D. Loken, "Mesostructures and the Tensile Strength and Fatigue Endurance of Aligned Fibre Composites", Polymers & Polymer Composites, 1, 253-60 (1993).

- M.R. Piggott and Y. (June) Xiong, "Visualization of Debonding of Fully and Partially Embedded Glass Fibres in Epoxy Resin", Comp. Sci. Tech, 52, 535-40, (1994)

- M. Khatibzadeh and M.R. Piggott, "The Effect of Fibre Alignment on Composite Strength II: The Strength of Angle Ply Laminates", Comp. Sci. Tech, 56, 1443-1451, (1996).

- M.R. Piggott, "Why Interface Testing Using Single Fibre Methods can be Misleading", Comp. Sci. Tech. 57, 965-974, (1997).

- M.R. Piggott, K. Liu and J. Wang, "New Experiments Suggest that all Shear and Some Tensile Failure Processes are Inappropriate Subjects for ASTM Standards", ASTM STP 1383, 324-333, (2000)

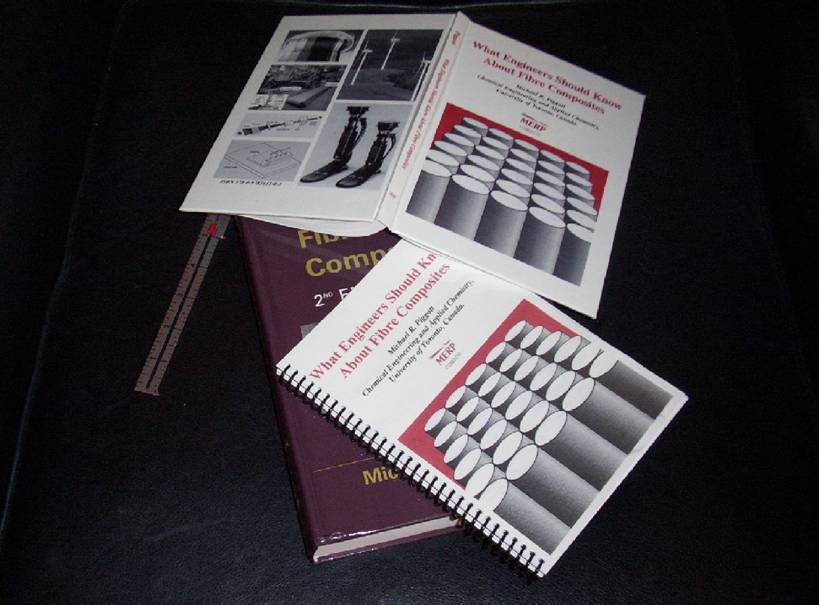

New Book

What Engineers Should Know

About Fibre Composites

by

Michael R. Piggott

Ph. D. (London), ARCS, SAMPE Fellow (retired)

Professor Emeritus, University of Toronto

Book available: Hard Cover and Soft cover,

spiral bound.

Handy size: pp.121 + xvi. About 145mm x 205mm; 14mm

thick

(The book underneath is Load Bearing Fibre Composites, 2nd Edition, published

by Kluwer in 2002)

ISBN 978-0-9783615-0-1 (Hard cover)

ISBN 978-0-9783615-1-8 (Spiral binding)

Also available free on the web by going to https://issuu.com/uoftengineering/docs/wescomp

or from the link to the Chemical Engineering website http://www.chem-eng.utoronto.ca/facultystaff/emeriti.htm

Synopsis

Chapter 1. Mechanics of Isotropic and Anisotropic Materials

In this introductory chapter we set out to do three things: 1) define the basic concepts needed for the development of the reader’s understanding of composites; 2) introduce the special terminology and symbols used in the book; and 3) describe some of the test methods used.

Chapter 2. Material Properties

In this chapter we will give some details of properties currently achieved with metals, plastics, ceramics and fibre composites. This is to give the reader a rational basis for materials choice. It will then be appreciated that, though excellent in many ways, composites are not suitable for use in all situations.

Chapter 3. Basic Concepts Needed for Design

We introduce here the essential information to enable you to design a fibre composite. We start from first principles, i.e. considering the unidirectional composite; how you estimate the stiffnesses and tensile strengths when the fibres go from end to end of the composite, do the same for the multidirectional laminate, and lastly introduce some design considerations.

Chapter 4. Laminate Resistance to Shear and Other Stressing Regimes

We have now got the tools we need to evaluate the stiffnesses, and tensile strengths but we still need to ensure that the composite will have adequate compressive strength and fatigue resistance. In this chapter we will discuss the resistance to these and other types of stress.

Chapter 5. Environmental Effects

Composites normally have to perform in less than ideal conditions. In this chapter we will discuss the resistance of a composite to the effects of heat, humidity and other aggressive environmental agents.

Chapter 6. How To Make and How to Use Composites

Having now learned how to design a composite and take into account the pitfalls of the reinforced plastic, we need to review the methods that are used to make composite structures like aeroplane wings, boats, bridges, canoes, cars, chemical plant, trains, prostheses, sports equipment and the countless other things made from these versatile materials. In addition, we will give examples to illustrate the wide range of employment of load bearing composites.

Problem

sets

Each chapter is followed by 12 – 21 problems, and selected answers.

Handy size: pp.120

+ xvi; about 145mm x 205 mm.

New Prices

Paper back; spiral bound: $C40, $US 40, ₤15, €35.

Hard cover: $C70, $US 70, ₤35, €70

A book containing worked solutions of the problems is available to certified teachers.

He now possesses the copyrights of Load Bearing Fibre Composites, originally published by Pergamon, and Load Bearing Fibre Composites, Second Edition published by Kluwer.

A few copies of the Second Edition

are still available from the author.

Also available free on the web by going to http://www.chem-eng.utoronto.ca/wp-content/uploads/2015/08/load-bearing-fibre-composites.pdf

or from the link to the Chemical Engineering website http://www.chem-eng.utoronto.ca/facultystaff/emeriti.htm

Book enquiries: j.clifford@utoronto.ca or micranpiggott@gmail.com