|

A STUDY ON Slotted Square and Rectangular Hollow Structural Section Connections

|

|||||||||||

|

1. Research Background and Objectives 3. Constitutive material model 4. Material change due to cold work 5. Model validation against the experimental results 6. Parametric study on the strength of slotted HSS members

|

|||||||||||

|

|

|||||||||||

|

, Hollow structural sections (HSS) are commonly and widely used in engineering structures, especially as welded tension and compression members in steel construction. , Shear

lag effect will lead to the non-uniform stress distribution at the

connection, which will reduce the effective net section for carrying the

load. , Korol

(1996) conducted some tests on square and rectangular HSS with L/w

ratio varying from 0.4 to 1.0. . Cheng et al. (1998) carried out some tests and numerical analysis on round sections with L/w ratio around 1. . S. Willibald et al.(2003) conducted some tests and numerical analysis on round HSS as well as literature review on the shear lag effect with gusset plate connections. . HSS tension members with welded connections are not explicitly covered in the current Canadian steel design code (CAN/CSA-S16.1-01 (2001)). The design method in the code is considered to be too conservative. Objectives

,

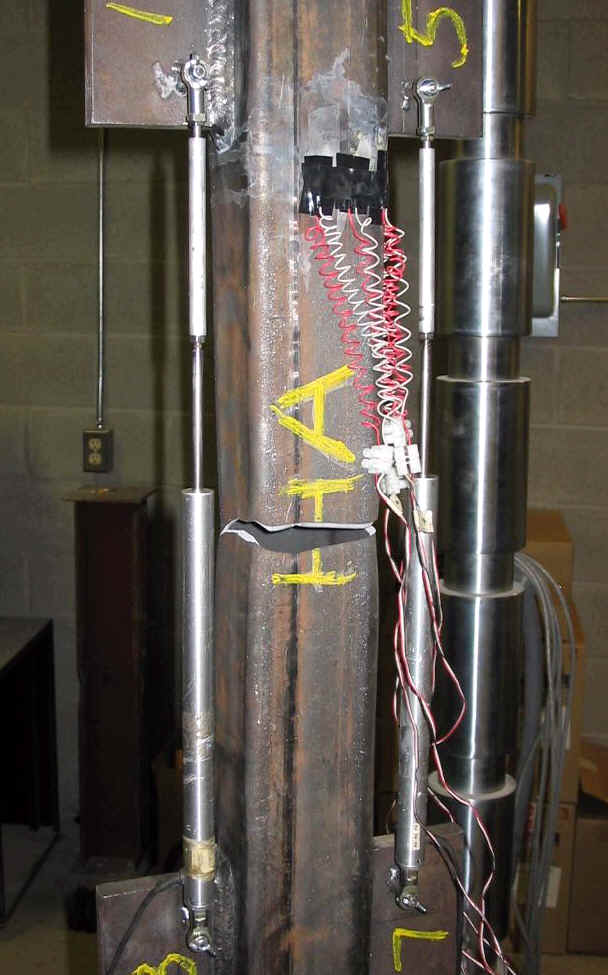

Conducting a serial uniaxial tension tests on full-scale slotted square and

rectangular HSS connections without end welding (26 specimens) and with

end welding (4 specimens) at the end of the gusset plate; ,

Develop and validate the finite element model for the test specimen,

study the performance of finite element model in terms of element

type, mesh sensitivity and execution efficiency; , Parametric study of the full strength of HSS members based on the validated numerical models. . Recommendations on provisions in the design codes for slotted HSS connections.

|

|||||||||||

| 3. Constitutive material model | |||||||||||

|

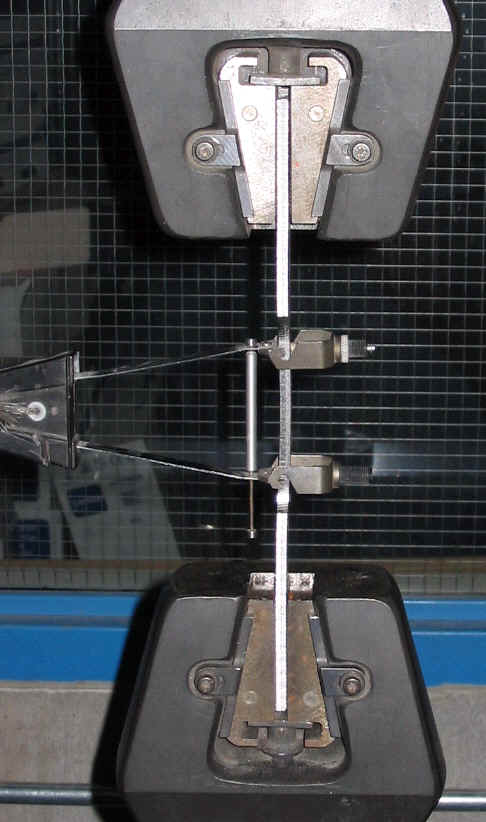

Research

Background , The engineering stress-strain curve does not give a true indication of the deformation characteristics of a metal because it is based entirely on the original dimensions of the specimen, and these dimensions change continuously during the coupon test. . Ductile metal (like structural steel ) coupon becomes unstable and necks down during the course of the test. Because the cross-sectional area is decreasing rapidly after peek load, the load required continuing deformation falls off. The average stress based on original area like wise decreases, and this produces the fall-off in the stress-strain curve beyond the point of maximum load. . An accurate material true stress versus strain relationship up to the instant of fracture is required in carrying out finite element analyses of structural connections. . Heng. A. Khoo et al (2002) proposed an experimental approach in addition to the traditional coupon test to obtain the part of the true stress versus strain curve after peak load by measuring the transverse deformation of the necking section. Scope of the Research , Conducting experiments on the coupons (total 39 ) cut from the HSS and gusset plates. A combined test technique of standard test procedure before peak load and measuring the transverse cross section change after peak load was employed. , Up to the peak load, the true stress versus true strain relationship can be converted directly from the engineering stress versus engineering strain data of a standard tension coupon test. , After the peak load, an iterative numerical method is used in obtaining the true stress versus true strain relationship. The trial true stress versus true strain relationship is adjusted iteratively until the numerical simulation agrees with the engineering stress versus cross sectional deformation data of the tension coupon test. The version of power-law stress versus strain function proposed by Naqvi and Khoo (2004) is adopted in generating the true stress versus true plastic strain relationship of the material.

Research

Background , Karren and Winter (1967) conducted coupon tests on the cold formed channel sections. Significant increase on both the yielding strength and tensile strength on the corners and the area adjacent to corners were observed. , The study by Abdel-Rahman et al. (1997) on cold-formed channel sections also showed that yield strength, ultimate tensile strength and ductility were all significantly changed at the corner of the section. At the corner, the yield strength was reported to be up to 47% higher and the ultimate tensile strength was up to 30% higher compared to that of the virgin material. Scope of the Research

|

|||||||||||

|

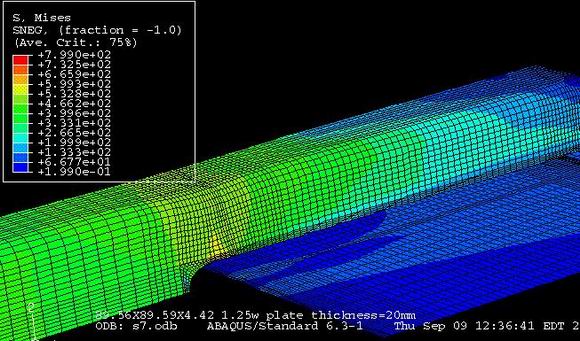

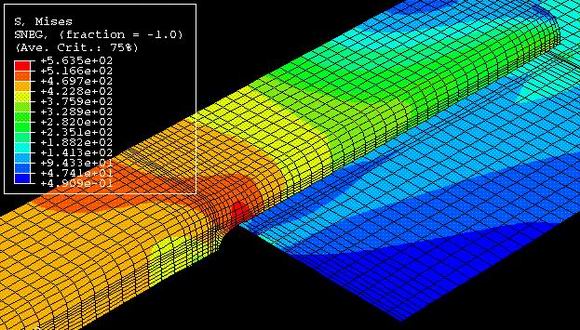

,

Finite element models are developed based on geometries of test specimens to

carry out numerical simulations of the slotted square and rectangular

connections. The developed finite element models are validated against

test results of HSS connections.

, Studies on the element type, equivalent plastic strain limit and mesh size are carried out before validating the finite element models. , The purpose of these studies is to develop reliable finite element models that can simulate the strength and behavior of square and rectangular HSS connections.

|

|||||||||||

|

Von.

Mises stress contour plot for numerical

model in Abaqus

|

|||||||||||

Model for 1/8 of a square HSS model

Model for 1/8 of a square HSS model Model for 1/8 of a rectangle HSS model

Model for 1/8 of a rectangle HSS model