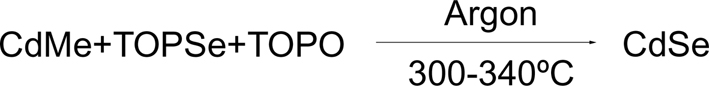

The QDs can be synthesized with Schlenk-line at high temperature.A traditional synthesis CdSe QDs procedure is to use organic compounds,such as TOPO, Dimethylcadnium(DMC), TOP and Selenium under high temperature and Argon protection to react.

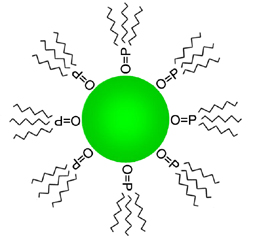

The QDs we got by use of the approch is coated

with organic compounds (TOPO, HDA, ODA etc.) Only can be dissolved

in organic solvent ( Hexanes, Chloroform, THF, Pyridine, Toluene etc.)and

has High Quantum Yield(>40%)

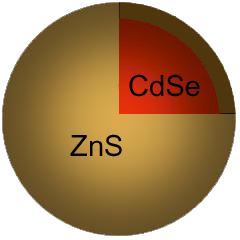

In order to improve the quantum yield of the QDs

and protect QDs from photooxide, the core-shell structure is used

to synthesize the Qds. As a shell, ZnS can increase the band gap of

the QDs so that the quantum yield can be raised to 80%.

As ligands, TOPO and HDA or ODA often be used to synthesis high quality quantum dots. the synthesis mechanism shows that HDA or ODA can improve the size distribution of the nanoparticlized form process and increase QDs quantum yield because of amine group action.

The Schlenk line ĘC 6-knob vacuum manifold,Fume hood, Glove box, Auto-temperature controllable heater,UV-Vis spectrophotometer and Spectrofluorometer are basic equipments and devices for the synthesis.

Tip1: As a standard, the properties of high quality QDs should be

Quantum Yield >40%-80%;FWHM<30nm;Photo-oxcided resistance.

Tip2: A protocol for QDs synthesis ( 550nm-640nm)

TOPO(90%) 8g, HDA(90%) 5g, DMC 0.2mmol, TOPSe soluton(1M) 4ml.

TOPO and HDA were put in 150ml three neck flask to degas for 30min at 150°C under stirring. Then add 0.2mmol DMC to continue degas for 15min.Afterwards,the argon was refilled into flask and the temperature was raised to 300°C. At this temperature point, the 4ml TOPSe was injected into flask rapidly. The temperature was kept at 280°C for QDs growth(the solution color was changed from yellow to dark).The sample was picked up at different time(from 30s to 4min). The different of color QDs can be got.At 270°C, add ZnS TOP solution 1-3ml for capping and cool down temperature rapidly.

TOPO

coated QDS structure