|

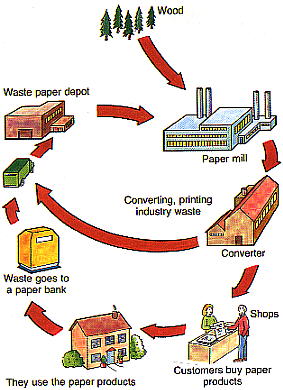

Making Pulp from Waste

(Click here to

see a diagram of the following process)

The global use of waste paper in the production

of paper and board is increasing. It reached about 85 million tonnes in 1990.

A further increase in the utilisation of

recycled paper is anticipated.

As forests in the UK account for only 10 per

cent of the total land area compared with 25 to 80 per cent elsewhere in Europe,

waste paper has been the backbone of the UK paper industry for many years. It is

seen as an essential resource and at present represents 55% of the fibre used by

the UK paper and board industry.

Recycling paper however does not, as many

believe, create a perfect cycle allowing paper to be made, used and then made

again. For instance there are limits to paper recovery. Paper is lost from the

cycle when used for permanent applications like record keeping, destroyed in use

or contaminated. Cellulose fibres cannot be recycled indefinitely. Virgin fibres

need to be continuously added to the cycle to replace exhausted fibres as this

diagram shows,

|

Utilising waste paper nevertheless makes

sound economic and environmental sense, particularly if the only alternative

is to send paper to landfill. Recycling, however, should not be seen as a

panacea for the environment. It too is an industrial process with

environmental implications which, like all industry, waste paper mills have

to endeavour to minimise.

The recovery of waste paper begins with its collection. It then has to be

sorted by hand into some 10 different groups of paper, all suitable for

different tasks. It is obviously much more efficient if paper can be

separated at source and this in fact is what the public is doing by

depositing their newspapers and magazines in special supermarket skips.

Office paper recycling schemes are becoming more common and separate bins

are installed so that the 'non-recyclables', such as envelopes and fax

papers, can be separated from the valuable office grades. |

Much of the paper sent to the mill will contain

contraries and must be processed to remove all unwanted materials (such as pins,

staples, and adhesive tape) the paper will have to be cleaned and contaminates

disposed of. Depending on the final intended use, inks will be dispersed or

removed by de-inking.

Uses for the contraries or 'sludge' are being

developed by waste paper using mills; some use de-inked sludge to generate

energy, others are developing uses such as composting and brick-making thus

reducing disposal to landfill.

|